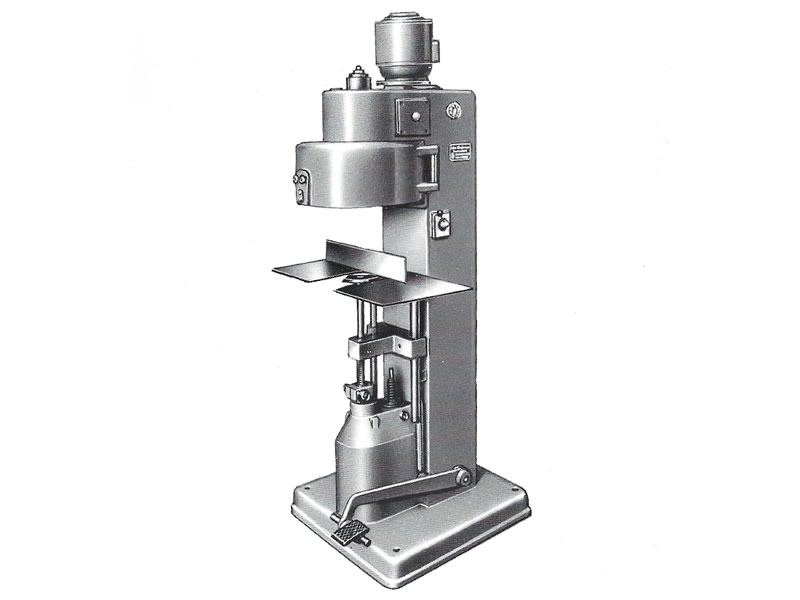

| Vertical seaming machine for round cans

GENERAL CHARACTERISTICS

This semi-automatic seamer for round cans is very efficient. This machine it’s very recommended for closing product filled cans. We suggest this machine for its easy use and its tooling change speed. Its functioning is especially quiet thanks to the toothed belts.

FUNCTIONING

The container with the lid, or with the overlapping bottom, is housed on the elevator plate which is controlled by the pedal. As soon as the container is strictly held between the plate and the seaming chuck, the seaming rollers are activated by means of a coupling. At the end of the operation the plate returns to the starting position automatically. The seaming chuck, in the initial position, protrudes slightly from the head protection to facilitate the centering of the can. The seaming of the bottoms and / or the lids takes place when the can is stationary, this makes it impossible for the contents to overflow like any accident due to the rotation of the containers.

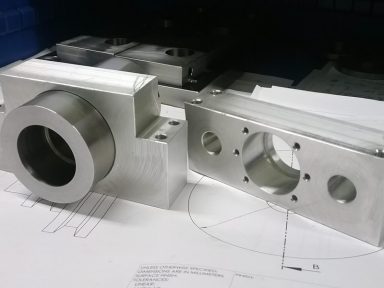

The seaming head equipped with four seaming rollers mounted on ball bearings, in a particularly stable and simplified construction, guarantees a completely safe closure. The seaming equipment, like all parts of the head, are easily accessible by opening the hinged protections.

The cans are supported on two levels, with adjustable height, between which the lifting plate slides. Thanks to the installation of ball and needle bearings, the machine runs smoothly, and the work time is minimized.

Upon request, the machine can be equipped with transport wheels to facilitate movement.

INSTALLATION

The machine’s installation is simple. The operations for changing the formats can be carried out in a few minutes, both as regards the spindle, seaming rollers and the elevator plate. The four seaming levers that carry the rollers are adjusted by means of threaded rods that ensure absolute adherence to the cams. The height of the head and of the rollers is adjustable.

START UP AND PRODUCTION CAPACITY

The machine is driven by a 1.1 Kw motor, 1500 rpm.

The motor on request can be supplied for other current.

The movement is transmitted by two toothed belts which require very little maintenance. The production capacity can reach 2000 cans/hour.

TECHNICAL DATA

Max Production: 2000 cans/hour

Diameters: from 35 to 250mm

Heights: from 20 to 400mm

Max sheet Thickness: 0.50mm

Plate stroke: 65mm

Power: 1,1 Kw

Weight: 570 Kg

Max dimensions: 196 x 80 x 109 cm

“It’s easier to love a brand when the love is reciprocated.”